Busbar punching, cutting and bending machine: 3 in 1, economical and efficient

SUNSHINE™ busbar machine have an annual sales volume of over 1,100 units due to their multi-functional and cost-effectiveness, and are highly favored in the electrical panel or high and low voltage switchgear manufacturing industries. Whether you require busbar punching, cutting, and bending, or require more complex busbar processing, SUNSHINE offers proven technical solutions to meet your aluminum and copper busbar processing needs.

Máquina de puncionamento de barramento CNC SS-50-3

$ Solicitar preço

Máquina de corte de barramento CNC SS-80-3

$ Solicitar preço

Máquina de barramento de cobre SS-30-3CNC

$ Solicitar preço

SUNSHINE™ standard 3-in-1 busbar machine features a three-station design consisting of a punching unit, a bending unit, and a cutting unit, integrating busbar punching, cutting, and bending functions into a single machine. Equipped with three high-power motors, it delivers a max hydraulic output of 800KN. Three people can operate the machine simultaneously without interrupting other workstations, significantly improving busbar processing efficiency. With a low initial investment cost, it is ideal for small-scale electrical panel manufacturers and switchgear factories with limited budgets.

- Three independent motors allow simultaneous operation of all stations.

- Processed sections are smooth and burr-free.

- Affordable and highly productive.

- Simple operation and easy to learn.

Entre em contato conosco para saber mais sobre nossa máquina de processamento de barramentos ou para solicitar melhor orçamento.

SUNSHINE™ standard 3-in-1 busbar machine only supports PLC in the bending unit, while the punching and cutting units lack PLC configuration. This is a key difference from professional 3-in-1 busbar machine. The bending unit’s PLC has built-in standard bending modes: six bending modles. Simply input the bending angle to easily achieve any busbar bending angle. The punching unit and cutting unit can only be manually calibrated through the ruler to calibrate the coordinates of the busbar processing position to achieve the punching and cutting processing effects.

If you have a sufficient budget and demand high production efficiency, please check out our PRO series: Professional 3-in-1 busbar machine. This series differs from the standard 3-in-1 busbar machine in that the punching, cutting, and bending units are all PLC-enabled, and the servo system is also added, with three PLC touch screens and four servo systems.

Whether you’re bending, punching, or cutting busbars, the operator simply enters the parameters, and Professional 3 in 1Busbar Machine automatically and quickly locates the busbar processing coordinates, eliminating the need for manual positioning using a ruler. This results in processing efficiency five times that of a standard 3-in-1 busbar machine. Another surprise is that the machine supports program memory storage, meaning the operator only needs to enter parameters once and can simply call up the stored program in the future.

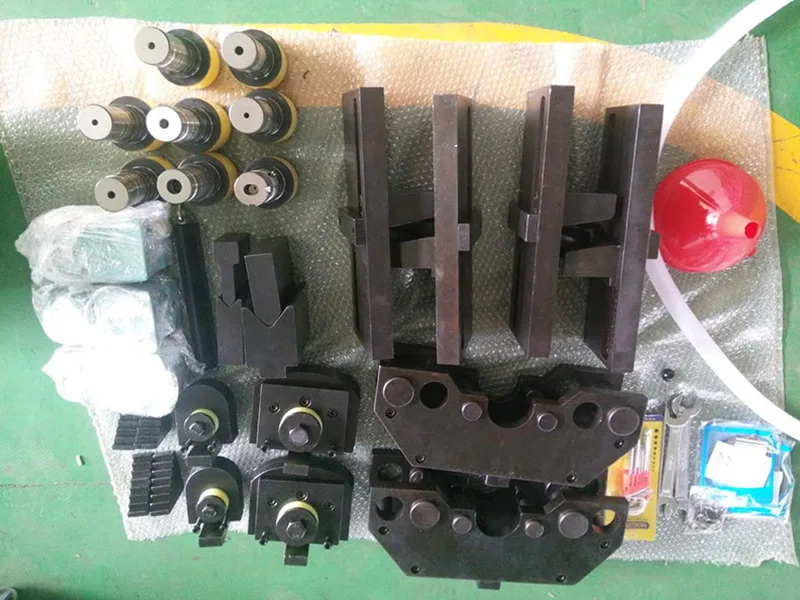

Mold list

Each of our busbar machines is standardly equipped with 5 sets bending molds, 8 sets punching molds and 1 set cutting mold. Our molds are made of Cr12Mov high-strength alloy steel, which has excellent wear resistance and strength, making the cross-section of busbar punching and cutting smooth and burr-free, and the service life is up to 30,000 times.

| Mold | Specification | Qty |

|---|---|---|

| Molde de perfuração redondo | Ø7, Ø9, Ø11, Ø13, Ø17 | 5 conjuntos |

| Molde de perfuração oval | Ø11×15, Ø13×18, Ø17×21 | 3 conjuntos |

| Molde de Dobra Vertical | R3, R5, R10, U-SHAPE | 4sets |

| Horizontal Bending Mold | R80 ou R50 | 1 conjunto |

| Molde de estampagem | / | 1 conjunto |

| Molde de corte | / | 1 conjunto |

Observação:The above molds are standard equipment and are free of charge. If your busbar bending requirements are unique, or if you require a punching mold with special specifications and shapes, please contact our technical engineer: Sra. Lisa e we can provide you with a one-on-one customized solution.

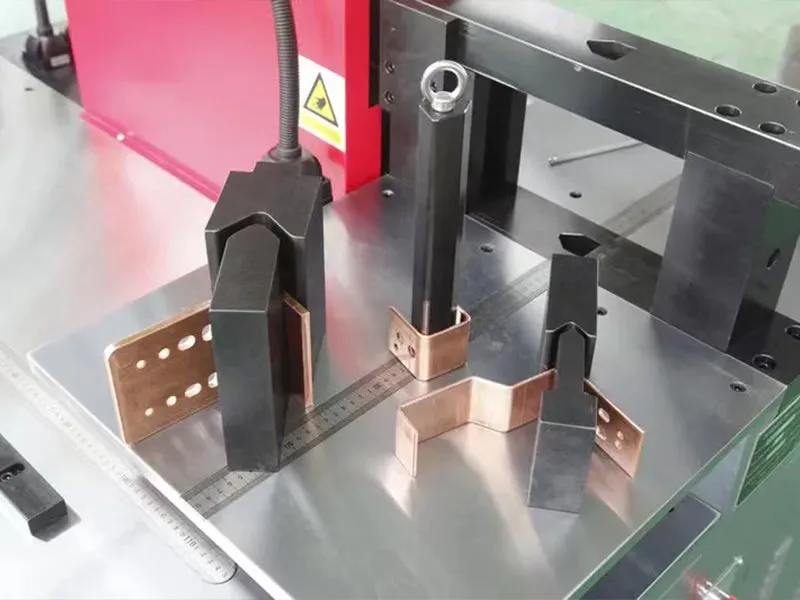

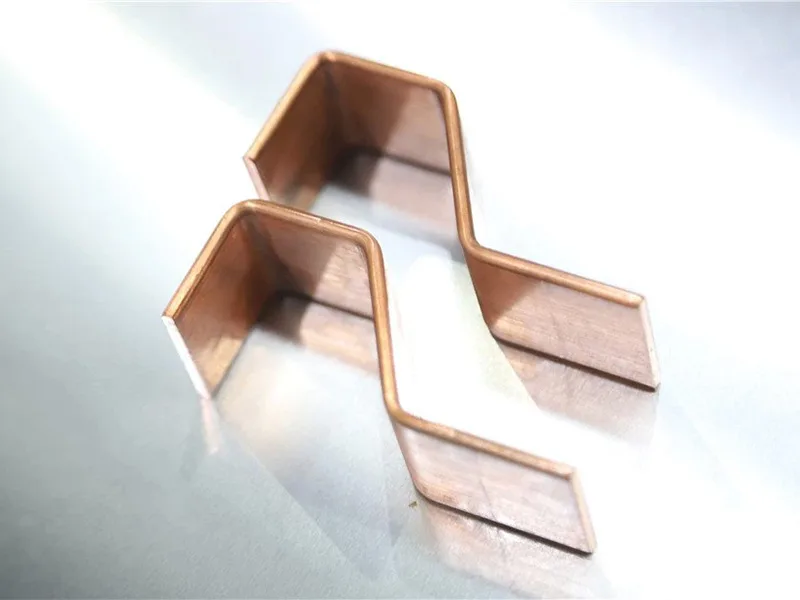

Galeria de imagens de amostra de barramento

A equipe técnica SUNSHINE™ tem insistido na iteração da tecnologia de processamento de barramentos para alcançar uma combinação perfeita entre software e hardware, de modo que cada barramento processado por cada dispositivo atenda aos padrões de projeto, a seção transversal do barramento é lisa e sem rebarbas, e garante que o desperdício de material de barramento de cobre seja minimizado e atenda aos rigorosos requisitos da indústria.

- Bending Mold: Vertical bending (R3, R5, R10), horizontal bending (R80/R50), U-bend, embossing, twisting

- Punching Mold: Round, oval, square, rectangle, chamfer, special shape

- Molde de corte

Entre em contato conosco se tiver dúvidas?

Mande-nos uma mensagem pelo WhatsApp +86-15562468863 para suporte técnico ou personalização.

Sobre nós

Até o momento, os fabricantes de equipamentos elétricos de 75 países e regiões em todo o mundo (incluindo Estados Unidos, Canadá, México, Brasil, Egito, Turquia, Itália, Grécia, Vietnã, Tailândia, Filipinas e Indonésia) escolheram SUNSHINE™ e MAC™ por suas soluções precisas, estáveis, eficientes e confiáveis de puncionamento, corte e dobra de barramentos. Com suas capacidades superiores de fabricação mecânica, As máquinas de barramento SUNSHINE™ são sinônimo de economia e multifuncionalidade, enquanto a MAC™, com sua sofisticada tecnologia CNC e software, é sinônimo de automação, eficiência e precisão.

SUNSHINE™

Com mais de 2.540 clientes satisfeitos e participação em mais de 58 eventos internacionais, continuamos comprometidos em fornecer equipamentos de fabricação de barramentos de classe mundial e suporte técnico ágil a qualquer hora e em qualquer lugar.

Nossos Serviços